not just welding

- Support a variety of weld types, fast switching

- Improve productivity and yield

- Greatly reduce the impact of poor workpiece consistency on welding quality

- The welding torch can be in the ideal position

- Compensation for production, equipment and operation tolerances

- For complex weldments, it can greatly reduce the workload of robot teaching and programming

- Some scenes can realize the robot exemption from teaching

- Non-contact welding seam tracking, saving fixture production costs for customer

- Seamless connection with CRP robots

- The sales and after-sales support of laser seam tracker and the robot are in the same team, reducing the time and cost of communication with customers

- Gap range: 1.5-20.0mm

- Horizontal error: 0.1mm

- Height error: 0.1mm

- Standard installation height: 330mm

- Average field of view width: 80mm

- Nearest height: 290mm

- The farthest height: 390mm

- Can be used for all kinds of gas shielded welding

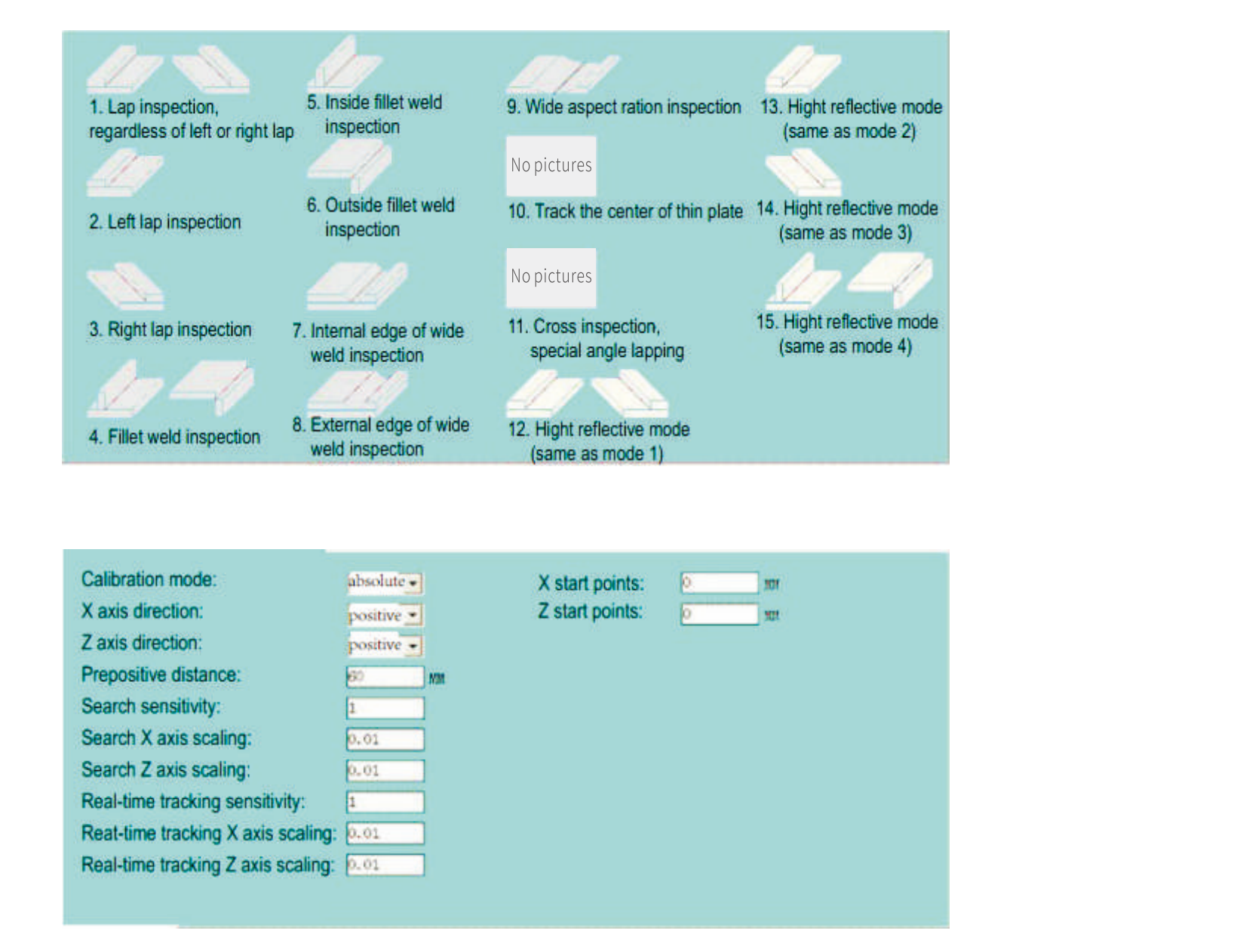

- A variety of weld shape options, suitable for different weld types; expert fuzzy control, intelligent identification of different weld characteristics

- According to the welding seam type, real-time display of current welding seam deviation, welding seam width, misalignment amount and other information to facilitate welding process optimization

- Real-time tracking of weld level, high and low directions

- Minimum forward-viewing distance 103mm

- Resistant to strong arc and splash

- Welding current <=500A

- It is mainly suitable for the scene requiring high visual distance and large field of view, such as fan, box interior and other storage point welding scenes. It also suitable for real-time tracking in large visual field and high visual field with strong anti-splash ability

- Limited application scenarios: some scenarios with limited space; For example, in tower foot welding, it needs a long time to weld.