not just welding

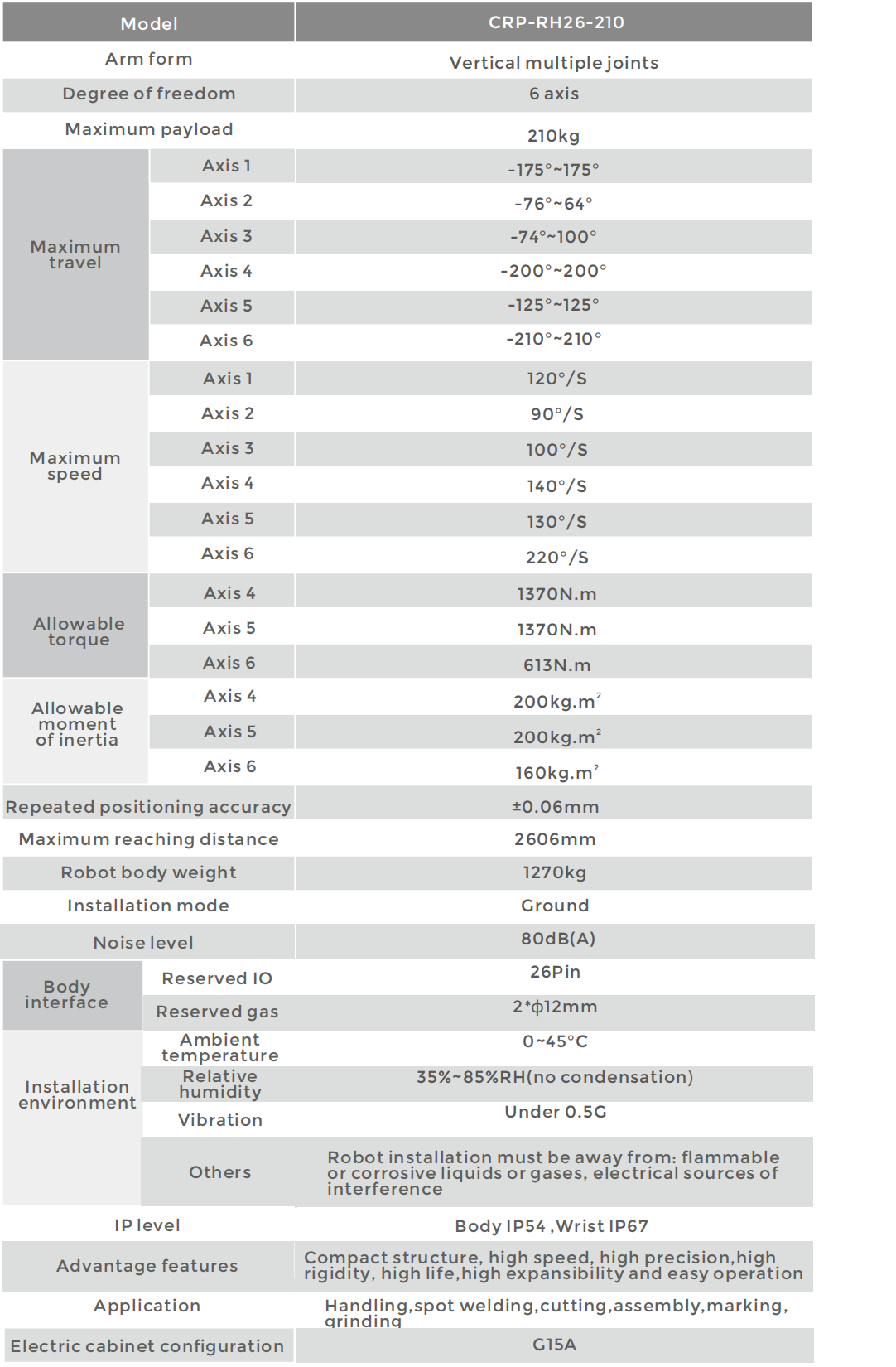

Arm span 2.6 meters, high rigidity, strong load capacity, more stable operation.

Adopt a hollow arm structure and built - in wrist cable, without considering the interference caused by the external winding mode with the neighboring robot or peripheral equipment.

Adopt a hollow arm structure and built - in wrist cable, without considering the interference caused by the external winding mode with the neighboring robot or peripheral equipment.

Adopt a hollow arm structure and built - in wrist cable, without considering the interference caused by the external winding mode with the neighboring robot or peripheral equipment.

The robot body adopts highly flexible special cable.

Built - in three - phase filter can effectively improve the performance of EMC and EMI.

The body provides Φ12mm dual - loop gas pipes and Φ19.5mm dual - loop water pipes to meet welding and transportation requirements.

Using high - speed, high - overload capacity servo motor, high - precision RV reducer and the latest anti - vibration control strategy, shorten the pitch operation time, optimize the gun shaft operation sequence of the servo welding torch, and significantly shorten the cycle time.

The installation area of the whole machine is small, which can achieve high density installation and wiring, and multiple units work together.

Simple structure, friendly operation interface, easy maintenance, easy to operate.