not just welding

light load controlcabinet

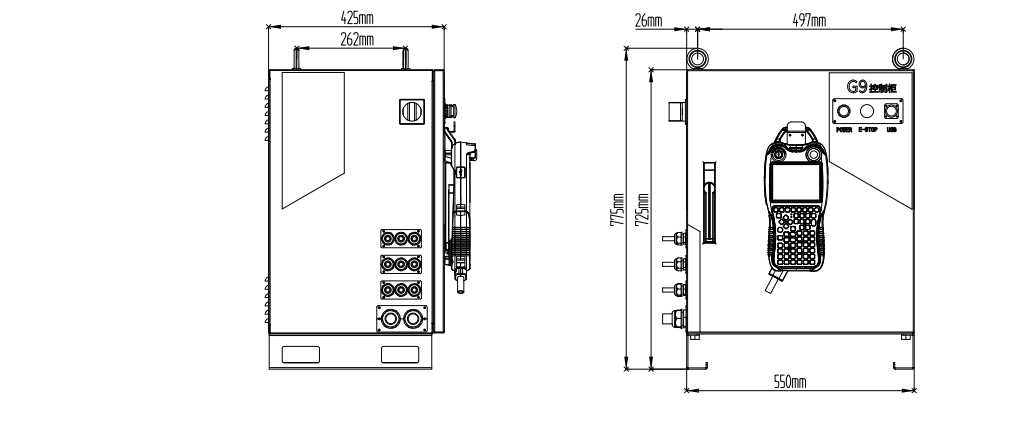

Using a split design

The electrical cabinet is mainly divided into a power room and a control room. The power room primarily houses heat-generating components, using multiple groups of fans+duct design to ensure good heat dissipation for these components. The control room is isolated from the power room to prevent dust and oil contamination, ensuring cleanliness in the control from being affected by dust and oil, which could lead to abnormal operation.

Multiple sets of anti-interference components

Power filters, isolation transformers, and dual-switch power supplies are used to ensure the stable and reliable operation of the control cabinet.

Built-in safety emergency stop board

Using imported forced-disconnection relays, dual-circuit emergency stop is provided externally. When any emergency stop button is pressed, the power circuit and servo unit are simultaneously and immediately processed to forcibly stop the robot’s movement, thereby achieving safe emergency stop.

Collision softening

When the anti-collision signal is effective, the system and driver respond simultaneously, quickly softening the attitude axis to avoid damage to the body and welding gun.

Automatic external power-on function

Ensure that the operator’s line of sight is diverted away from the robot to safeguard the operator’s personal safety.

Energy-saving mode

Effectively reduce standby energy consumption. At the same time, prevent personnel from accidentally entering the robot area during standby status, which can cause injury.

Equipped with a three-phase transformer, isolated at 380V and 200V, the power supply is more stable. It also contains a three-phase filter, effectively isolating external interference and preventing internal interference from being output.

Dual power supply design to avoid internal power interference.